In copper wire processing, accuracy is a key indicator for measuring product quality. This wire drawing machine, with its intelligent control system, can accurately control the copper wire diameter tolerance within ± 0.001mm, far exceeding the industry average level. During high-speed drawing, by monitoring and adjusting the drawing speed, tension, and temperature in real time, the internal crystal structure of the copper wire is ensured to be uniform, avoiding internal defects caused by stress concentration during processing, and ensuring that each copper wire has consistent mechanical and electrical properties. For example, in the production of ultrafine copper wire for precision electronic components, its surface roughness can reach Ra0.05 μ m or less, ensuring the smoothness of the copper wire at the microscopic level, effectively reducing the resistance loss during electronic signal transmission, and improving the performance stability of electronic components.

Efficient production capacity and flexible process adaptation

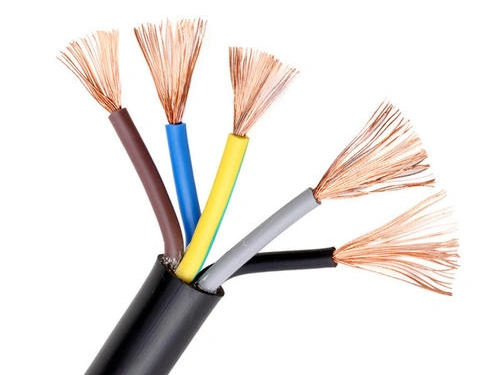

The innovative transmission system and variable frequency speed regulation technology endow the wire drawing machine with efficient production capacity. When producing copper wire for ordinary wires and cables on a large scale, its maximum drawing speed can reach 50m/s, which is more than 30% higher than traditional equipment, greatly shortening the production cycle and improving production efficiency. At the same time, it can switch and adjust process parameters in just a few minutes to meet the processing needs of copper wires of different materials and specifications. Whether it is processing phosphorus deoxidized copper with high hardness or oxygen free copper with strict plasticity requirements, the intelligent control system can automatically match the optimal drawing process to achieve continuous and efficient production from coarse wire to fine wire, meeting diverse market demands.

Significant cost savings and low maintenance requirements

From the perspective of long-term operating costs, this wire drawing machine has obvious advantages. On the one hand, due to its adoption of advanced energy-saving technology and efficient transmission system, the energy consumption in the production process is reduced by about 20% compared to traditional equipment, effectively saving electricity costs. On the other hand, the selection of high-strength wear-resistant alloy materials for key components, combined with special heat treatment and surface strengthening processes, greatly extends the service life of the equipment. Under normal production conditions, the equipment's fault free operation time can reach over 8000 hours, which is 50% higher than traditional equipment and reduces downtime and maintenance costs caused by equipment failures. Meanwhile, the modular design of the equipment makes component replacement more convenient, further reducing maintenance difficulty and costs.

Deep industry adaptation and customized services

This wire drawing machine has deep adaptability in multiple industries related to copper wire, such as electronics, electrical, and communication. We provide customized services to meet the special needs of different industries. In the electronics industry, to meet the requirements of chip manufacturing for ultra-high purity and precision of copper wire, we can customize drawing machines equipped with higher precision filtering systems and online detection devices to ensure that the impurity content of copper wire is controlled at an extremely low level, meeting the strict standards of chip manufacturing. In the communication industry, based on the requirements of 5G and future communication technologies for cable performance, we can customize and optimize the drawing process and equipment parameters to produce copper wire with lower signal transmission loss and higher anti-interference performance, which helps to upgrade the technology of the communication industry.