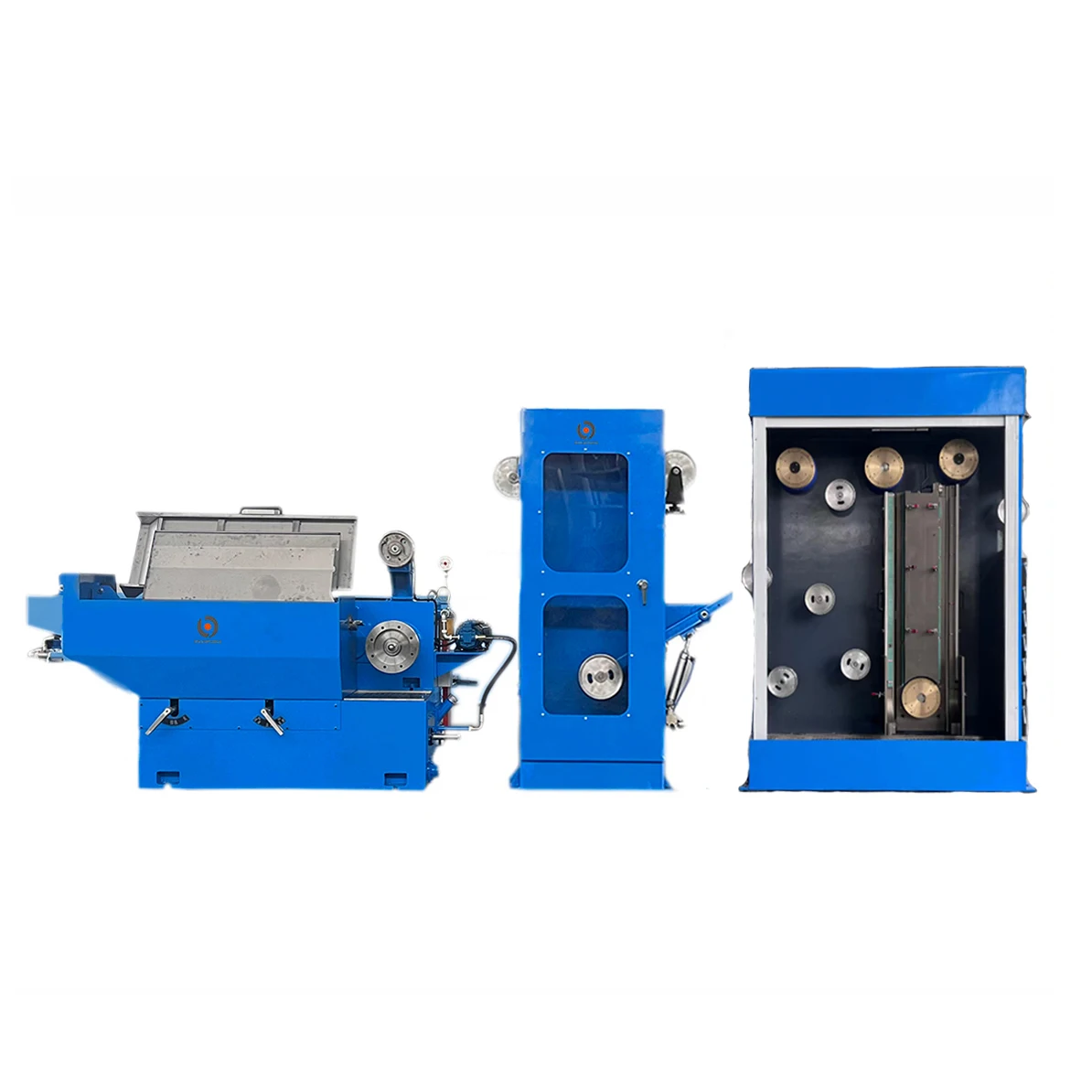

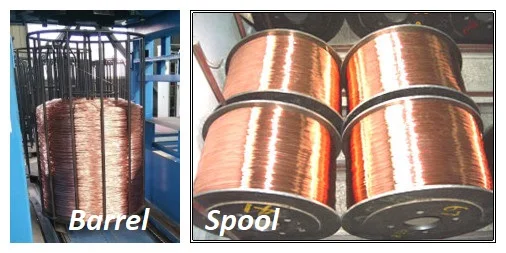

Intermediate Copper Wire Drawing Machine with Annealer is used for drawing and annealing copper wire from 3.0mm to 1.13-2.78mm.Outlet wire can be collected by single spool take up or coiler.

Machine type |

BRN-9DHT |

Control system |

PLC with touch screen |

Inverter control |

Dual inverter control |

Drawing dies No./max. |

9 |

Inlet diameter |

Ø 2.6- 3.5mm |

Out diameter |

Ø1.1- 2.78mm |

Drawing line speed |

1200mpm/max |

Slip ratio of m/c |

18% |

Fix speed capstan slip ratio |

15.5% |

Frame |

Ironed cast |

Capstan |

Ceramic plasma capstan |

Main motor |

55kw |

Spooler motor |

11kw |

Capstan dia.(max) |

Ø 300mm |

Fix speed capstan dia. |

Ø 300mm |

Spool bobbin size |

Ø 500-630mm OR according to customers |

1) What’s the payment terms?

Standard type is 30% T/T as deposit, 70% T/T before shipping.

2) How about the after-sell service?

Engineer will be dispatched at needed.

3)How much need pay for after-sell service?

The buyer provides engineer's roundtrip flight tickets, board and lodging,

the security as well as each person of daily wage.

4)What kind of Gurantee you can offer?

12 months since shipping date and charge for repair the whole life.

5) Can you support complete project instead of single machine?

Yes, besides machine, the whole solutions for raw material, auxiliary parts,worker training etc can be offer